Chinese Researchers Develop Supercapacitor From Dried Leaves Three Times Better Than Graphene

Chinese scientists have discovered a way to synthesize leaves of deciduous phoenix trees — found in abundance in north China — into a porous carbon material that can be used to produce high-tech electronics capable of enhancing information storage.

According to the study reported in the Journal of Renewable and Sustainable Energy, through a multi-step, yet simple process the leaves could be incorporated into electrodes as active materials, and give rise to highly efficient super capacitors.

Super capacitive materials hold great promise for a wide variety of energy storage needs, particularly in computer technology and hybrid or electric vehicles, according to a Science Daily article.

Tests to determine the electrical property of the material revealed it was indeed a super capacitor, and its 367 Farads/gram recorded capacitance was over three times higher than graphene super capacitors.

High performance super capacitors are already widely used to increase the efficiency of hybrid electric vehicles in several ways. Today’s hybrid vehicles typically turn off the engine completely when the car comes to a stop, however briefly, and then very efficiently start it again using energy stored in super capacitors.

But, the main shortcoming of existing super capacitors is their low energy density, meaning that the amount of energy supercapacitors can store per unit weight is very small, particularly when compared to batteries.

The material developed can be used to counter this shortcoming in the near future, and lead to improved super capacitors that can magnify the efficiency of our electronic devices.

The research, led by Hongfang Ma of Qilu University of Technology, has been heavily focused on looking for ways to convert waste biomass into porous carbon materials that can be used in energy storage technology.

The process simply corrodes the surface of the carbon from the organic matter by burning and ionizing.

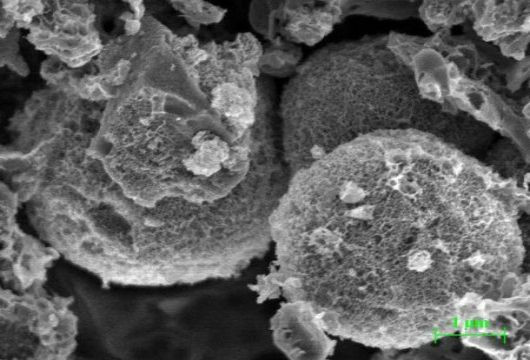

The dried leaves are first ground into a powder, and then heated to 428 degree Fahrenheit for 12 hours. This produces a powder composed of tiny carbon microspheres. The carbon ‘microspheres’ or carbon particles become extremely porous. The presence of pores increases the surface area of the particle. These pores give the material its special electronic properties.

These microspheres are then treated with a solution of potassium hydroxide — which is an electrolyte like salt water — and heated by increasing the temperature in a series of steps from 842 to 1472 F.

The team has branched its research out to find other plants that may produce organic waste capable of making capacitors.

According to a phys.org article, the team and others have successfully converted potato waste, corn straw, pine wood, rice straw and other agricultural wastes into carbon electrode materials.

Professor Ma and her colleagues hope to improve even further on the electrochemical properties of porous carbon materials by optimizing the preparation process and allowing for doping or modification of the raw materials.

The super capacitive nature derived from the porosity of the carbon particles obtained from phoenix tree leaves recorded a value higher than those recorded with carbon powders derived from other bio waste sources.

The fine scale porous structure seems to enhance the super capacitive properties this material exhibits. Researchers also concluded that the contact between electrolyte ions and the surface of the carbon spheres, as well as the enhanced transfer of the ions because they get a wider area for diffusion through the pores gives the material its higher capacitive value.

© Copyright IBTimes 2024. All rights reserved.