Fuel From Algae In One Hour Or Less: 'Pressure Cooker' Technique Spins Green Oil

In less time that it takes you to do your laundry, researchers at the Pacific Northwest National Laboratory can spin algae into oil.

Biofuel is often cited alongside wind and solar power in the laundry list of alternative energy sources, but the term actually covers a wide range of processes that aim to turn carbon-containing materials into fuel. Grasses, corn or sugarcane can be turned into ethanol; the golden scum from the local restaurant’s fryalator can end up as biodiesel. Algae is another growing biofuel niche, one that that has seen ups and downs.

The advantages of algae as a fuel source is that it reproduces rapidly. But most approaches to date have focused on breeding strains that produce high levels of fatty acids, which are relatively easy to turn into fuel. But these fatty algae strains don't grow as quickly as normal algae.

“An alternative algae utilization strategy is to grow algae in a wild and/or mixed culture at optimum growth conditions in order to maximize total biomass without consideration of fatty acid production,” scientist and lead researcher Douglas Elliott and his colleagues wrote in the journal Algal Research in October.

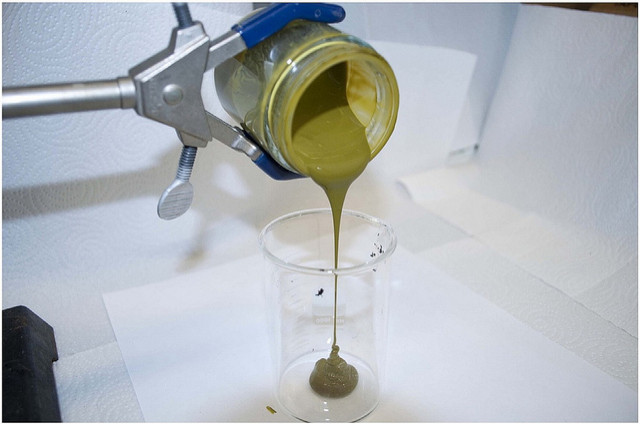

Elliott and colleagues have found a way to transform a slurry of algae and water into crude oil by exposing it to very high pressure -- 3,000 pounds per square inch, about the same pressure of the average scuba tank -- and water heated to 660 degrees Fahrenheit. These forces rip the algae up and convert it into a mixture of hydrocarbons similar to light crude oil, along with clean water, fuel gas and nutrients that can be used to grow more algae.

"It's a bit like using a pressure cooker, only the pressures and temperatures we use are much higher," Elliott said in a statement. "In a sense, we are duplicating the process in the Earth that converted algae into oil over the course of millions of years. We're just doing it much, much faster."

The process is particularly unique in that the researchers can feed the reaction using wet algae. Other algae processing techniques require extra energy to dry out the material.

"Not having to dry the algae is a big win in this process; that cuts the cost a great deal," Elliott said. "Then there are bonuses, like being able to extract usable gas from the water and then recycle the remaining water and nutrients to help grow more algae, which further reduces costs."

About 53 percent of the algae will end up converted into biocrude, according to the team’s recent experiments.

“[The] key thing about the process is that it is continuous-flow: you can keep stuffing algae in the front even as biocrude flows out the far end, which means that it can be operated continuously, keeping the heat in the system and raising the efficiency (although, in practice, the test setup was never run for more than a day),” John Timmer wrote at Ars Technica.

There are still some major hurdles that algae-based fuels will have to clear before they can be a viable alternative. A recent analysis by environmental policy researchers from Imperial College London found that many algal cultivation methods consume more energy than they produce.

"Cost is the big roadblock for algae-based fuel," Elliott said. "We believe that the process we've created will help make algae biofuels much more economical."

© Copyright IBTimes 2024. All rights reserved.