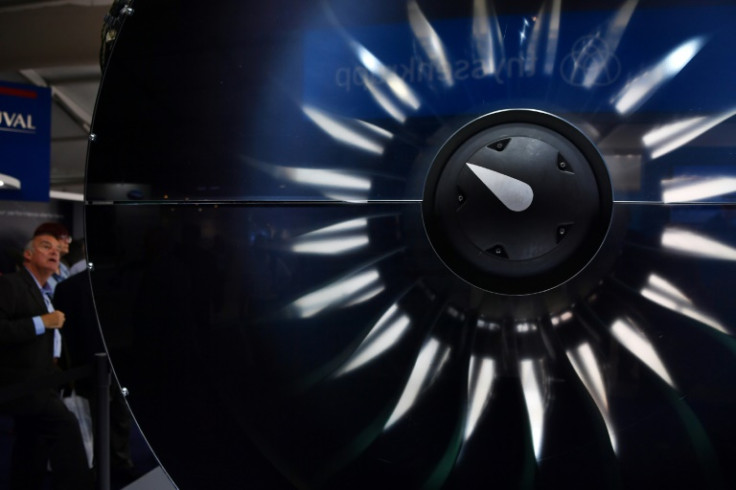

GE Aerospace To Invest Over $1 Billion In Aircraft Maintenance And Repair Facilities

Increased demand for travel has warranted more planes in the air, ushering plans for GE Aerospace to invest more than $1 billion in an upgrade to its maintenance, repair, and overhaul (MRO) facilities.

Upgrading the said facilities will be able to shorten turnaround time for new customers, Reuters reported. The shortage in new planes has led companies to keep older planes up in the air for a bit longer, as aircraft manufacturers have to contend with insufficient labor, aircraft parts, as well as raw materials.

The planned MRO investments of GE will add equipment and engine test cells, apart from providing the company with cutting-edge technology, and enhanced inspection techniques, according to AFP.

"Our customers are experiencing strong air travel demand, and we are investing to increase our capacity and efficiency so we can meet their growing needs and keep their planes flying safely and reliably. With this major investment, we are reinforcing our longstanding focus on safety, quality, and delivery for our customers and the flying public," said Russell Stokes, the president and CEO of GE Aerospace, Commercial Engines and Services.

The global airline industry finds the limited capacity at MRO shops as one of the major constraints it faces. Several airline CEOs consider the delay in engine repair as a bigger issue than production at Airbus.

Bain & Company, a consulting firm, stated that after the pandemic, the turnaround times increased at repair shops. For legacy engines, there was an increase of 35%, and for new-generation engines, an increase of 150% was seen. The firm also stated that on the average, it takes two to three months for airlines to secure a slot at an MRO.

Delays incurred while repairing an engine would be on the agenda when industry leaders meet in Farnborough, England, next week for an upcoming air show.

GE Aerospace had previously told investors that it would be investing more on its manufacturing facilities, around $650 million, which would help increase production. In addition, it also plans to invest more in its repair shops so that it could reduce turnaround time for its customers.

Now, as the fleet continues to expand, there is a growing demand for CFM LEAP engines, and the majority of the investment will be supporting this increase in demand. The LEAP engines are the one that power the Boeing and Airbus narrowbody aircraft.

© Copyright IBTimes 2025. All rights reserved.