Hyperelastic 3D-Printed Synthetic Bone That Induces Natural Regeneration, Growth

Bone implants, while always a complicated matter, are easier to perform in adults who are already fully grown, but for children whose bones are still growing, it makes the process a lot more troublesome, requiring further surgeries later in life. But a new method developed by researchers could make things much simpler for pediatric patients.

A team from Northwestern University in Illinois “has developed a 3D-printable ink that produces a synthetic bone implant that rapidly induces bone regeneration and growth,” according to a statement on the university’s website. The hyperelastic material “whose shape can be easily customized” was tested with human stem cells and animal models, and its results were published Wednesday.

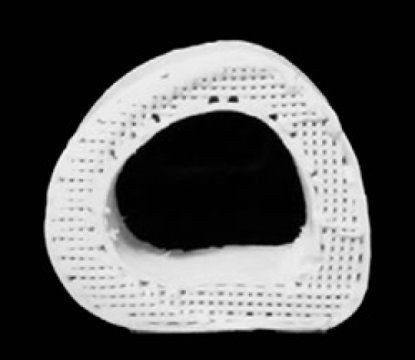

The research was led by Ramille Shah, who specializes in biomaterials. The faux bone biomaterial mixes a calcium mineral called hydroxyapatite, which is found naturally in human bone and a biodegradable polymer used in various medical applications. The resultant material is highly elastic, robust and porous at the same time.

“Porosity is huge when it comes to tissue regeneration, because you want cells and blood vessels to infiltrate the scaffold. Our 3D structure has different levels of porosity that is advantageous for its physical and biological properties,” Shah said in the statement.

The specific composition of the biomaterial — 90 percent hydroxyapatite — helps induce rapid bone regeneration.

Shah explained: “Cells can sense the hydroxyapatite and respond to its bioactivity. When you put stem cells on our scaffolds, they turn into bone cells and start to up-regulate their expression of bone specific genes. This is in the absence of any other osteo-inducing substances. It’s just the interaction between the cells and the material itself.”

Other substances, such as antibiotics, can also be added to the ink to prevent infection after surgery.

The conventional method of bone grafting involves taking existing bone from another part of the patient’s body and shaping it to fit exactly in the area it is needed. This leaves the area where the bone is taken from vulnerable to further complications. The new technique has significant advantages over the conventional method, including the time taken for the procedure.

“The turnaround time for an implant that’s specialized for a customer could be within 24 hours. That could change the world of craniofacial and orthopedic surgery, and, I hope, will improve patient outcomes,” Shah said.

The study was published in the journal Science Translational Medicine under the title “Hyperelastic ‘bone’: A highly versatile, growth factor–free, osteoregenerative, scalable, and surgically friendly biomaterial,” and Adam E. Jukus from Shah’s team was its first author.

© Copyright IBTimes 2025. All rights reserved.