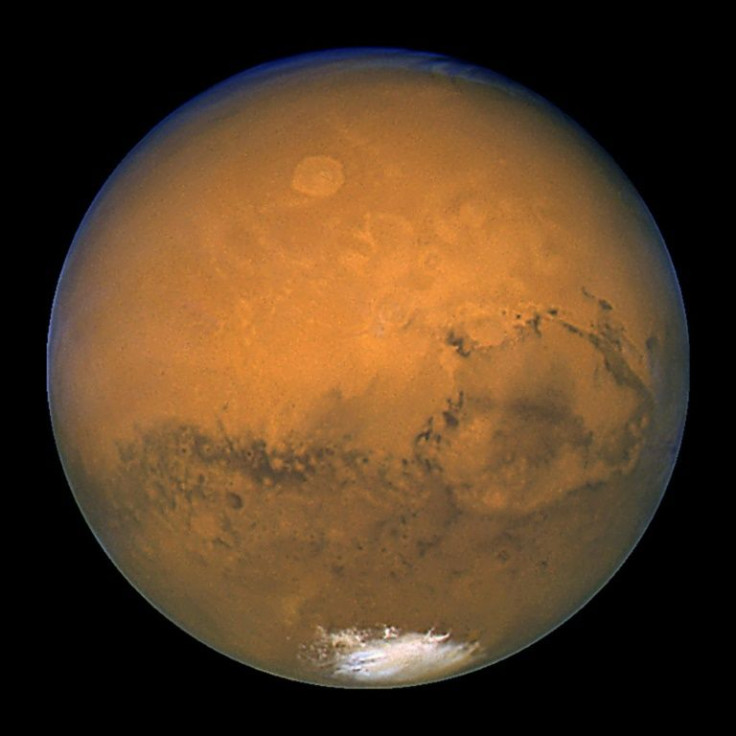

Martian Soil Could Be Used As 3D Printing Material, New Research Shows

KEY POINTS

- The study used simulated martian regolith and titanium alloy as a base for printing material

- The results could reduce the weight carried from Earth, saving millions of dollars

- For a NASA space shuttle, the cost to ferry just 2.2 lb to low-Earth orbit is about $54,000

Our trip to the Red Planet may become more cost-effective in the future as new research has uncovered the potential use of martian soil as a 3D printing material. If found applicable, this could indicate the possibility of manufacturing tools right on the surface of Mars.

Researchers at Washington State University (WSU) used simulated martian regolith along with titanium alloy as a base for printing material.

Simulated martian regolith is a black powdery substance that is supposed to be similar to the rocky, inorganic material found on the surface of Mars.

The findings of the study, published in the International Journal of Applied Ceramic Technology, have great implications for future missions to Mars.

"In space, 3D printing is something that has to happen if we want to think of a manned mission because we really cannot carry everything from here," said researcher Amit Bandyopadhyay, a professor in WSU's School of Mechanical and Materials Engineering. "And if we forgot something, we cannot come back to get it."

Manufacturing on Mars would also help cut down the cost of logistics. For a NASA space shuttle, the cost to ferry every kilogram (2.2 pounds) is about $54,000, that too, to a low Earth orbit. In contrast, the average distance between Earth and Mars is 140 million miles, driving up the cost exponentially.

For the study, researchers mixed simulated martian regolith in different proportions ranging from five percent to 100 percent with the titanium alloy. The resulting mixtures were tested for durability as printing material.

The five percent martian regolith mix proved to be better than the titanium alloy when used on its own. It could be used to build lightweight structures that can withstand heavy loads.

"It gives you a better, higher strength and hardness material, so that can perform significantly better in some applications," Bandyopadhyay said.

On the other hand, the 100 percent martian regolith material, cracked upon cooling. However, researchers believe this concentration of the martian regolith can be used as a coat to protect against radiation.

The process of 3D printing involved melting the ingredients to 3,632 degrees Fahrenheit (2,000 degrees Celsius) and then feeding them to a 3D printer to construct pieces of different sizes and shapes.

Building on the findings of this study, future research may find better printing materials with the use of different metals or 3D printing techniques.

"This establishes that [3D printing with regolith] is possible, and maybe we should think in this direction because it's not just making plastic parts, which are weak, but metal-ceramic composite parts, which are strong and can be used for any kind of structural parts," Bandyopadhyay said in the statement.

© Copyright IBTimes 2024. All rights reserved.