Researchers Discover ‘Self-Healing’ Metal [VIDEO]

“Self-healing” metal may soon be a real thing. Researchers discovered that, under the right conditions, breaks can be healed and this development could lead to new materials, such as structural metal or parts used in aircraft or oil wells, that last longer and are much safer.

Researchers from the Massachusetts Institute of Technology, MIT, discovered that, rather than further damaging the metal, applying enough tension to a crack can heal the metal. The researchers, Michael Demkowicz, a professor at MIT, and Guoqiang Xu, a graduate student at the university, thought this healing process was an error.

In theory, applying tension, pulling the crack apart, should have led to a larger crack, ultimately breaking the metal. “Instead of extending, [the crack] was closing up. First, we figured out that, indeed, nothing was wrong. The next question was: ‘Why is this happening?’” said Demkowicz in a statement.

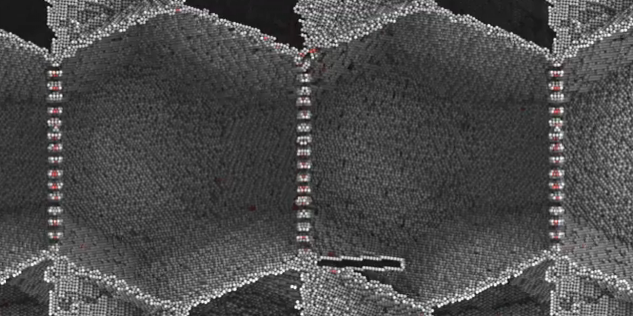

According to the researchers, metal is made up of “tiny crystalline grains” that shape its properties and strengths. Testing nickel, Demkowicz and Xu discovered that if the grains were lined up properly, applied tension would cause the cracks to close. This process, known as grain boundary migration, is what allows for the crack to heal but it’s only possible between boundaries that occur partway into the metal, at a molecular level.

Grain migration boundaries are considered defects. The particular defect that allows for self-healing is called a “disclination” and researchers discovered these defects have incredibly strong stress fields. According to the researchers, these stress fields reverse the applied force. For the experiment, researchers were pulling and the stress field reversed that tension, pushing the break and healing the crack.

This discovery has plenty of potential practical applications. The researchers want to conduct new studies that let them control the behavior of disclinations in metal alloys. Nickel, for example, is used as a base for superalloys, or high-performance alloys. These superalloys are used in airplanes, oil wells and other industrial fields.

Structural damage caused by tiny fractures, called metal fatigue, could be reduced or prevented by developing alloys with this self-healing capability. “If you can figure out how to prevent those nanocracks, or heal them once they form, or prevent them from propagating, this would be the kind of thing you would use to improve the lifetime or safety of a component,” said Demkowicz in a statement.

In the computer simulation video, a crack can be seen in one of the crystalline grains. As stress is applied, the crack heals.

© Copyright IBTimes 2024. All rights reserved.