Safe and Enclosed Laser Engraving Machines: A Practical Guide for New Users

Due to their accuracy, speed, and versatility in working with different materials, laser engraving machines have gained traction from industries such as small firms and creative artisans. However, novices must know how these machines work and, more importantly, how to operate them safely. This guide will cover the fundamentals of laser engraving machines, why enclosed systems should be used at all times, and safety measures beginners should observe.

What Is a Laser Engraving Machine?

An engraving machine can be defined as an appliance equipped with a focused laser beam that can cut, engrave, or rasterize a pattern, design, or text on a number of materials, such as wood, metals, acrylic, leather, and even glass. The action of the laser basically vaporizes the material's surface, resulting in permanent marking. Laser engraving machines can create markings with so much detail alongside rapidity, which is an unrealistic feature for machines that do not use lasers.

Why Purchase an Enclosed Laser Engraving Machine?

One of the most crucial considerations when purchasing a laser engraving machine is whether it is within an enclosure or not. The protective elements are designed to surround the laser and the working area. There are several advantages associated with this design:

Advanced Protection: Enclosed machines prevent unintentional interaction with the laser beam. This is essential because even insignificant amounts of direct contact with laser light can result in severe eye injuries or burns. The enclosure means that the laser is safely and securely contained within a defined space where members are kept safe.

Control of Fumes and Particles: When the material being engraved is subjected to laser engraving, fumes and particles harmful to health can be emitted. These enclosed systems are sometimes provided with fans that help remove such by-products from the user's vicinity and improve the conditions in a workspace.

Prevention of Unintentional Interference: An enclosed system also aids in decreasing the chances of unintended interference while engaging in the process of engraving. It prevents the insertion of either foreign bodies or hands into the working space, which may interfere with the operations of the machine or the safety of the user.

Cleaner Work Environment: An enclosed design contains debris and particles, achieving a clean workspace. This especially applies to the machine's future maintenance since its performance will remain intact for a longer time.

What Is the Working Principle of a Laser Engraving Machine?

A laser engraving machine works, and it includes various devices.

- Laser Source: The material will be specially engraved using the concentrated light beam produced by this laser source. For example, a CO2 laser can be used to engrave plastic and fiber lasers can be used to engrave metals.

- Motion Control System: The laser head is moved over the material across the X and Y axes through computer-controlled motors, which are part of this system. The movement is precise and allows the laser to etch in the finest of details.

- Power Supply: The power supply modifies the laser´s strength, thus modifying the depth and shade of the engraving. The settings are increased for thicker materials or deeper engravings.

- Cooling System: Several laser engraving machines have cooling systems, particularly when engraving is required for extended periods.

Take Your Designs to the Next Level with the Creality Falcon 2 Pro Laser Engraver and Cutter

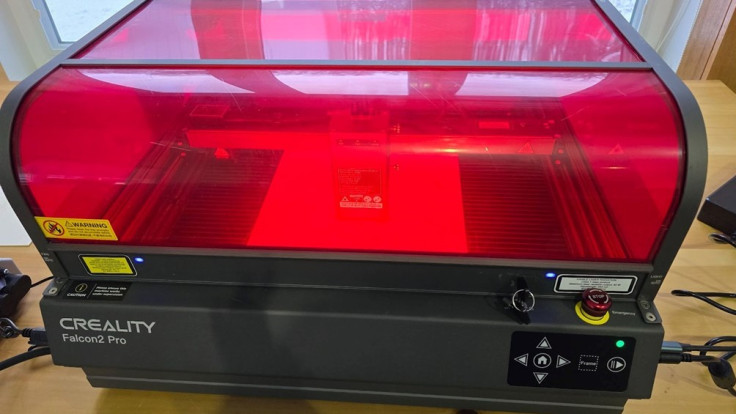

The Creality Falcon2 Pro is a high-performance, versatile machine designed for both hobbyists and professionals in engraving and cutting. With its 40W laser power, this device can handle a wide range of materials, including wood, acrylic, leather, cardboard, and more.

The Falcon 2 Pro features an enclosed design that provides a safe working environment by filtering harmful laser light. This design also helps control fumes and enhances overall safety during operation. Equipped with a built-in camera for precise design alignment and real-time previews, the Falcon 2 Pro allows users to achieve detailed, accurate engravings and cuts with ease.

The machine is user-friendly, compatible with popular software like LightBurn and LaserGRBL, and can be easily connected to a computer via USB. The integrated cooling system ensures the laser module operates efficiently, while its compact footprint makes it suitable for both home-based and professional settings.

Whether you're creating intricate designs or custom products or simply experimenting with laser cutting, the Creality Falcon 2 Pro Enclosed Laser Engraver and Cutter offers the performance, precision, and safety features needed for various projects.

Creality Falcon 2 Pro Features

The Creality Falcon 2 Pro Enclosed Laser Engraver and Cutter is designed to deliver exceptional performance with a range of powerful features. It is equipped with options for two laser heads: a 40W head, ideal for cutting thick materials and engraving large items, and a 1.6W head, suitable for detailed and fine engraving work. The interchangeable heads allow users to switch seamlessly between tasks depending on their specific needs. Its key features include:

- Powerful & Fast: With an engraving speed of up to 25,000mm/min, the Falcon 2 Pro ensures efficient, high-speed work, making it ideal for both professional and hobbyist use.

- Class 1 Safety: FDA-certified for safety, the machine offers 360° visibility while operating, ensuring users can monitor the process without compromising on protection.

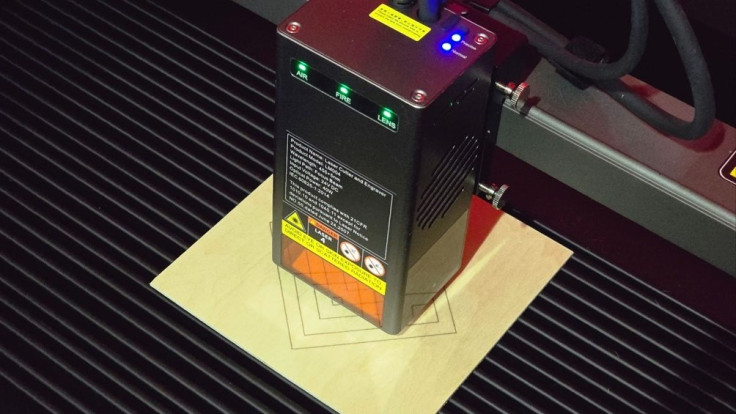

- Precise Positioning: Equipped with advanced pilot technology, the Falcon 2 Pro guarantees accurate design alignment for precise engravings and cuts every time.

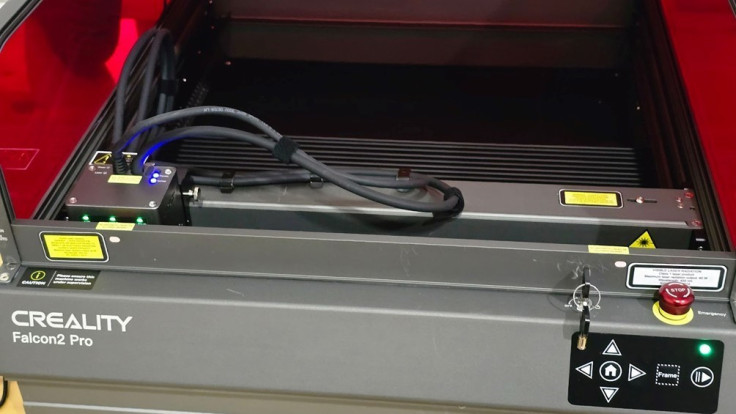

- Fence-Type Cooling Base: The machine incorporates a fence-type cooling base, which is highly effective in dissipating heat during operation. This design ensures better thermal management and prolongs the lifespan of the equipment.

- Crumb-Organizing Drawer: A dedicated drawer is included for collecting and organizing debris and crumbs generated during the cutting and engraving processes. This feature simplifies cleanup and maintenance.

- Fully Enclosed Laser Housing: The housing is designed to be fully enclosed and features flexible push-and-pull functionality. This provides both safety and convenience during operation.

- Internal Top-Mounted Camera: Equipped with an internal top-mounted camera, the machine integrates seamlessly with LightBurn software for precise positioning and enhanced control. A demonstration showcases the accuracy and ease of operation achieved with this feature.

- Intelligent Detection and Air Assist: The system includes three levels of intelligent detection and an integrated adjustable air assist system, continuing the successful design principles seen in the Falcon2 model.

- Expansion Components: The machine supports additional components, such as an external air purifier, allowing users to customize and optimize their working environment.

- Uninterrupted Workflow: If the machine is paused during operation, it can seamlessly resume work from the exact pause position after being restarted. This ensures efficiency and minimizes the risk of errors in ongoing projects.

These features come together to make the Creality Falcon 2 Pro an excellent choice for anyone seeking precision, speed, and safety in their laser engraving and cutting projects.

A Step-by-Step Guide for New Users of Creality Falcon 2 Pro Enclosed Laser Engraver and Cutter

This guide will help you quickly start using the Creality Falcon 2 Pro enclosed laser engraver and cutter. We'll walk you through the setup, operation, and maintenance, covering everything from unboxing and software installation to choosing materials and adjusting settings for optimal results. By the end of this guide, you'll be ready to start creating with confidence!

Getting Started

1. Unbox and Set Up the Laser Engraver

- Carefully unbox the Falcon 2 Pro and remove any protective packaging.

- Set up the machine on a stable, level surface in a well-ventilated area. Ensure there is adequate space around the engraver for proper airflow and easy access.

- Connect the power cord to the machine and plug it into a wall outlet.

- Attach any additional components, such as the laser module, if not pre-installed.

2. Install the Software

- For the latest software, visit the Creality Falcon website or refer to the manual. Most Creality engravers are compatible with LightBurn or LaserGRBL software.

- Install the software on your computer following the instructions provided in the installation guide.

- Launch the software and connect the engraver to your computer using a USB cable or Wi-Fi (depending on the machine's capabilities).

Preparing for Engraving or Cutting

3. Level the Surface

- Ensure that the surface of the machine's work area is flat and level. This is crucial for ensuring consistent engraving or cutting depth.

- Use the focus tool to adjust the height of the laser head. The correct focal length is essential to get precise results. Adjust the laser module's height to ensure the laser focus is at the proper distance from the material.

4. Select Your Material

- The Falcon 2 Pro can engrave and cut a wide range of materials, including wood, acrylic, leather, and fabric.

- Choose your material based on the type of project. Place the material flat on the engraving bed and secure it with clamps or tape, if necessary.

5. Focus the Laser

- The Falcon 2 Pro may have an autofocus feature, or you can manually adjust the laser head to focus it. Proper focusing ensures precise, sharp engravings and cuts.

- If the laser requires manual focus, place the included focus tool between the material and the laser head. Adjust the height until the tool fits snugly between them.

Using the Laser Engraver

6. Load Your Design

- Open the engraving or cutting design in the software. Standard file formats include SVG, DXF, PNG, or JPG.

- Import the design into the software, ensuring it fits the size of the material you're working with.

7. Set the Parameters

- Set the appropriate engraving or cutting parameters, such as speed, power, and passes. Refer to the material guide for recommended settings.

- Engraving: For engraving, reduce the laser power and increase the speed to avoid burning through the material.

- Cutting: Increase the power and reduce the speed for clean cuts.

8. Preview the Design

- Use the software's "Preview" feature to ensure the design fits within the material and does not exceed the engraver's boundaries.

- Check that the laser head's starting point is correctly aligned with the workpiece.

9. Start the Engraving or Cutting Process

- Once everything is set up, hit the Start button in the software to begin the engraving or cutting process.

- Monitor the process closely, especially during the first few minutes, to ensure everything is running smoothly and safely.

After Engraving or Cutting

10. Monitor the Process

- Stay nearby during engraving or cutting to monitor the machine's performance. If the material starts to warp or there are signs of fire, stop the process immediately and adjust the settings.

- Keep the enclosure closed while the machine is in operation to contain any fumes and to protect the user from laser exposure.

11. Finishing the Project

- Once the laser finishes the engraving or cutting process, the machine will automatically stop.

- Allow the material to cool down before removing it from the work area.

- If necessary, use a brush or air compressor to remove any remaining debris or soot from the surface of the material.

12. Shut Down the Machine

- Turn off the laser engraver and disconnect it from the power source when not in use.

- Store the machine in a safe place, away from dust or moisture.

Maintenance and Care

13. Regular Cleaning

- Clean the lens and mirror of the laser module regularly using a soft, lint-free cloth. This ensures the laser's efficiency and longevity.

- Wipe down the laser engraver's bed to remove any residue or dust from the workpiece.

14. Check for Wear

- Periodically inspect the moving parts of the machine (rails, wheels, belts) to ensure they are in good working condition. Lubricate moving parts as needed.

15. Keep the Enclosure Clean

- Ensure the machine's enclosure remains free of smoke or soot build-up, as this can obstruct airflow and impact performance.

By following these steps, you can safely and effectively use the Creality Falcon 2 Pro Enclosed Laser Engraver and Cutter for a wide range of engraving and cutting projects. Always prioritize safety and ensure you're using the proper materials and settings for the best results. Purchase the Creality Falcon 2 Pro using code FNPALL10 (not combinable with page discounts) and explore our New Year discounts.

Safety Tips for New Users

Never Open the Machine's Covers During Operation: Regardless of any other task at hand, the covers and doors of the units should not be opened during the working cycle. The laser beam is exceedingly intense and would be dangerous if someone came into contact with it.

Use Proper Eye Protection: It's advisable always to have laser safety goggles even if you're working with fully enclosed equipment or machinery ventilation or doing some other operation because the machine is enclosed inside.

Ventilation Is Key: Check whether the exhaust systems give out sights and whether the working atmosphere is ventilated. This will help remove harmful gases that emanate from the engraving process.

Avoid Flammable Materials: While engraving, it is best to use materials that do not have a risk of combustion. Also, engraving on materials that would emit combustible gases is not advisable, and it is sensible to have fire blankets within reach.

Regular Maintenance: It has always been effective to clean the device, including the lens, mirrors, and filters, on a constant basis to enhance its effectiveness and avoid equipment failure, which might result in accidents.

Conclusion

Laser engraving machines are effective devices for both professionals and amateurs alike, particularly when they are properly encased. As long as you are implementing the basic knowledge of how these machines function and the essential safety requirements, you are bound to have an easy, productive time. Always remember that while these machines are engineered for precision and efficiency, safety should be the first concern. When the right tools and safety measures are in place, laser engraving can be an enjoyable skill.

© Copyright IBTimes 2024. All rights reserved.