Scientists Use Simulated Moondust To Forge Bricks In A Solar Furnace

Scientists associated with the European Space Agency (ESA) have demonstrated that it is possible to create bricks at least as strong as those made of gypsum using simulated moondust. The proof-of-concept experiment, carried out at the DLR German Aerospace Center in Cologne, proves that it is possible — at least in theory — for future lunar colonists to build habitats using material available in situ.

Scientists and astronomers have long believed that before humankind can undertake a voyage to Mars, another trip to the moon is imperative. The logic is unquestionable — the moon, with its hostile environment and extremely low gravity, can serve as a testing ground for technology that might one day be used to establish colonies on the red planet.

Read: China, Europe May Put A Base On The Moon

Imagine, if you will, that you are an astronaut who has just landed on the moon with the aim of establishing a permanent colony. The first thing you would need to do would be to build habitats that can not only withstand the vast extremes of temperature the lunar surface oscillates between (250 degrees Fahrenheit when the sunlight hits the surface to below -240 degrees when it’s dark.) but one that can also protect you from deadly cosmic rays.

Here’s where this hypothetical astronaut runs into a problem.

Building massive, and habitable, structures on the moon can be accomplished either by hauling heavy construction material on spaceships from Earth (something that would make every moon mission dauntingly expensive), or by using material available in situ to 3D print habitats at a fraction of the cost.

And this is what ESA scientists have now succeeded in doing. Of course, since the scientists didn’t have access to large enough quantities of actual lunar soil, they used commercially available simulated moondust created using terrestrial volcanic material that had been processed to mimic the composition and grain sizes of genuine moondust.

“We took simulated lunar material and cooked it in a solar furnace. This was done on a 3D printer table, to bake successive 0.1 mm layers of moondust at 1000°C. We can complete a 20 x 10 x 3 cm brick for building in around five hours,” ESA materials engineer Advenit Makaya explained in a statement released Wednesday.

The researchers used a solar furnace at the DLR German Aerospace Center facility consisting of 147 curved mirrors that focused sunlight into a high-temperature beam to melt the soil grains together. Although the bricks thus created showed some warping at the edges (because their edges cool faster than the centre), the project was, on the whole, successful in demonstrating that in-situ lunar construction is a feasible option.

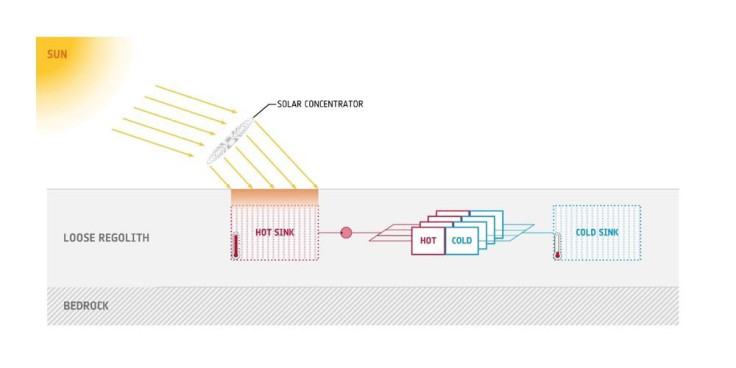

Building habitats is not the only thing the lunar regolith may be used for in the future. Scientists associated with ESA’s General Studies Programme recently unveiled another concept plan that envisioned using processed soil to create a heat exchange system that would be used to keep astronauts warm during cold lunar nights.

“Up until now, radioactive heat and power sources have been the preferred solution for lunar habitats, but these would multiply the cost and complexity of any expedition,” ESA’s Moritz Fontaine said at the time. “So we’re exploring a more sustainable solution, using the capacity of moondust to absorb and store energy when hit by sunlight, then releasing this energy during the lunar night.”

© Copyright IBTimes 2024. All rights reserved.