Stronger Green Packaging Solutions Are Finally A Reality

INO Armor®, a New York/Hong Kong-based biomaterials company, has teamed up with the silkworm to create an all-natural, superior-performance alternative for shipping and protecting fragile goods, with far-reaching benefits for the environment, consumers, and business. International Business Times unpacks INO Armor's founding, which was shaped by a near-fatal tragic event, and explores the impact of this new technology as businesses globally increasingly shift towards this class of better performing green materials.

Over time, Mother Nature has provided mankind with some of the best ideas for addressing many of the most challenging problems we face—from the prehistoric era through the Industrial Revolution to the age of AI today. Using nature as our guide and copycatting the natural designs and processes right in front of us is known as biomimicry.

And from the Wright brothers' inspiration by the Laysan albatross in 1903, to DuPont Chemist Stephanie Kwolek discovering the framework for bulletproof-Kevlar from the silk of the golden orb-weaving spider in 1965, and the development of AI neural networks based on our own brain's structure, this biomimicry continues to drive some of society's most notable and elegant steps forward.

With this nature-human partnership in mind, today, by harnessing the ingenuity of the industrious and long-domesticated silkworm, INO Armor has developed a new type of reusable material that is not only non-pollutive and fully compostable but is functionally superior to current toxic fillers.

For thousands of years, silkworms—small, diligent, dare I say charming creatures—have mastered the art of biomaterial production, turning mulberry leaves into silk, a fiber celebrated for its strength, flexibility, and biodegradability, making them the perfect models for sustainable material innovation.

INO Armor's silk derived materials have dramatic implications for operators not only in the shipping & logistics and wine & spirits spaces but essentially any large or small business shipping goods currently using standard, toxic shipping materials du jour. While INO Armor's solutions help address the massive and immediate problem of plastic and foam waste, they offer more resilient protection for everything from expensive liquor bottles and fine art to valuable goods and even the human skull (INO Armor's origin).

Threading Trauma into Innovation

But the genesis of INO Armor's solutions didn't begin by sitting around watching unassuming silkworms spin their glorious little marvels. It began unexpectedly and rather tragically on midtown Manhattan's Third Avenue, when a speeding New York City yellow cab slammed directly into INO Armor founder Charlie Maddock. With the tremendous impact, Maddock shattered multiple bones and half of Maddock's skull needed to be removed. It also left him in a coma for weeks, followed by seven months of intense rehabilitation.

"Because I was given a second chance at life, we have been able to develop something that ensures other people will be safer and benefits business," stated Maddock.

But amid the harrowing event and over the course of Maddock's recovery, another unexpected bond formed between the patient and the surgeon who saved his life. Dr. Howard Riina, a highly regarded NYU neurosurgeon who developed a close friendship with Maddock, would later join forces to establish The Charles Maddock Foundation (a nonprofit dedicated to advancing the understanding and treatment of traumatic brain injuries) and later help lay the foundation for INO Armor's inception.

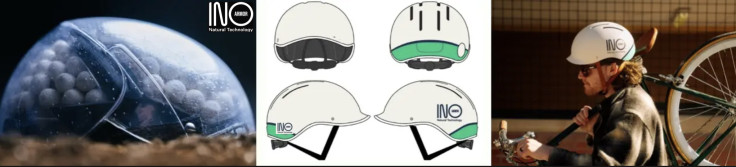

From the accident and his profound connection with Dr. Riina, Maddock was introduced to a network of brilliant minds in the field—including Professor Fritz Vollrath, a leading Oxford University expert in silk materials. What began as a conversation about replacing EPS foam in bike helmets quickly evolved into a mission to revolutionize the broader world of impact protection. With Riina and Vollrath's expertise, Maddock assembled a team of researchers, engineers, and designers to develop a sustainable, high-performance alternative—one that better protects people, products, and the planet.

Unwrapping A Green Future With More Resilient Packaging

After the company's 2020 inception, INO Armor pioneered the first 100% compostable bio-prototype of its silk pillow technology for helmets, which outperformed standard use synthetic EPS foam in regulated impact tests. Recognizing the material's resilience, broader applications, and monetization potential, INO Armor quickly tapped into high-demand markets.

"While everyone wants to go green, we focused on making products that actually performed better and are scalable for our clients. I think that our traction has been a tribute to that," explained Maddock.

And with $2 million in funding raised from top-tier institutions and notable ultra-high-net-worth families, it has gained impressive market traction. This momentum has been driven by securing major clients like Matthew McConaughey's Pantalones Tequila, and SROA Capital, which owns and operates 650 self-storage facilities across 31 states.

Through these partnerships, SROA is replacing bubble wrap with INO Armor's biodegradable packing material across its nationwide portfolio, and Pantalones began utilizing an all-natural, eco-mailer bearing the brand's name which also doubles as a handsome bottle tote for consumers. With the latter, INO Armor is optimistic this new eco-mailer/tote-bag product will become commonplace in the world's airports for travelers' duty-free liquor bottle purchases.

Beyond this product, Maddock notes the company is in late-stage partnership discussions with numerous companies and operators, as the tech can be applied in many different ways and forms.

Maddock "We started by building a better-performing bike helmet and quickly saw massive opportunity and interest in packaging. If you need to protect an important item and are open to using a natural system, there's nothing better than INO Armor."

But despite the clear need for sustainability on a global level with billions of metric tons of shipping-related waste annually, individual operators have struggled to find viable green alternatives that maintain both performance and profitability.

INO Armor's product development focused on addressing these challenges with superior solutions that saved companies money and spared consumers the headaches associated with damaged shipments. Given over 85 million parcels are damaged in transit annually in the U.S. alone, INO Armor's more protective alternatives to weaker synthetic bubble wraps reduce breakage, improving shipping reliability all while helping the bottom-line.

Going Beyond Green with Durability

"While INO Armor's wraps and bags stay true to our environmentally-friendly core, we've proven that the green option can also deliver superior performance," notes Tara Hobbs, Hong Kong-based VP of Product.

Hobbs, a seasoned hardware product development executive with a background in environmental policy, has held key management roles in scaling early stage companies (Hammerhead, Ampd Energy), after a foundation of nearly a decade at SolarCity through its IPO and acquisition by Tesla.

Hobbs explains that in the first round of rigorous product testing, INO's patented silk cocoon technology outperformed standard EPS foam in CPSC helmet drop tests compared to retail biking helmets. For the biking, alpine, football, baseball & equestrian spaces the company believes its products can make a notable impact to mitigate concussion risk for both sports enthusiasts & professional athletes.

In tests outlining the efficacy for a new potential client in the fine arts space, INOArmor wrap not only proved stronger and used 40% less material, but also reduced packing time and required no special tools. It was only slightly more expensive than lower-quality synthetic alternatives, which take up to one million years to decompose.

"When I met Charlie and learned about INO Armor's technology, I knew I had to drive the development and scale of these incredibly exciting materials. This is a once-in-a-lifetime opportunity to redefine impact protection," asserted Hobbs.

Cocooning From Silk to Scale

As the company looks ahead, it is currently seeking additional capital to fuel growth to meet rising demand and build out the supply chain. As the company advances further on its sustainable packaging goals, it continues to draw from the legacy of the silkworm's cocoon—one of nature's earliest protective designs, dating back more than 200 million years ago. From this ancient natural blueprint, INO Armor is weaving the world's next green chapter—hand in hand with nature, and guided by the tiny master spinners who have perfected the art for centuries.

© Copyright IBTimes 2024. All rights reserved.