Why American Manufacturing Matters: MacroAir Fans Has Made A Commitment To Quality, Innovation And Values

The Industrial High Volume, Low Speed Fans Market (HVLS) is on a remarkable trajectory. In 2024, the market was valued at $500 million, with projections indicating it will reach $1.2 billion by 2033, an astonishing compound annual growth rate (CAGR) of 10.5% from 2026 to 2033. According to the U.S. Department of Energy, the sector is expected to continue growing at a CAGR of 5.6% through 2030, driven by rising energy costs, increasing sustainability mandates, and a heightened focus on workplace comfort and efficiency.

As businesses search for cost-effective and energy-efficient climate solutions, the demand for HVLS fans is surging. These large-diameter fans significantly reduce energy costs by as much as 30% during summer months, depending on geography, making them indispensable for agriculture, warehouses, factories, gyms, and commercial spaces. But in a competitive landscape, where many manufacturers have turned to overseas production to cut costs, one company remains steadfast in its commitment to American-made excellence: MacroAir Fans.

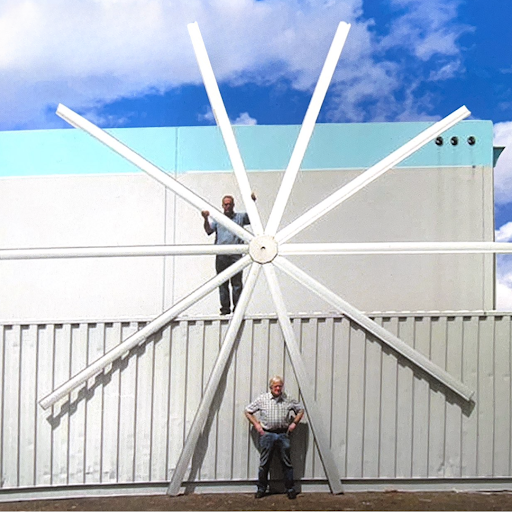

Founded back in 1998, MacroAir pioneered fan technology, revolutionizing air movement and climate control. Unlike others that rely on outsourced manufacturing, MacroAir proudly designs, engineers, and manufactures its products in the U.S. — and the company wouldn't have it any other way.

"MacroAir has been doing this for decades," says daughter of co-founder Eddie Boyd, Sheila Riley, Senior Vice President of Operations. "Yes, we're modernizing. Yes, we're growing with the times. But when we control the engineering, design, and manufacturing, that's when we get the best results. And that's what we want to give our clients."

For MacroAir, American manufacturing isn't just a buzzword: it's a philosophy ingrained deeply into its ecosystem — quality, accountability, and ensuring every fan meets the highest standards before it reaches the customer.

Manufacturing right in front of them allows MacroAir to oversee every stage of production, ensuring superior craftsmanship and durability. By keeping engineering and design teams close to the manufacturing floor, MacroAir eliminates the risks of miscommunication and diluted quality.

MacroAir fans are built in San Bernardino, California, and every fan exceeds the minimum 60% requirement of the Build America, Buy America Act. This commitment ensures compliance with strict federal procurement standards, making MacroAir products eligible for government-funded projects requiring American-made equipment. In addition, because MacroAir exceeds the minimum requirements, it has greater control over its pricing for customers and is able to maintain stability in current international market conditions.

Because MacroAir controls its manufacturing, it can rapidly innovate and adapt to customer needs. The company collaborates directly with engineers and end-users to refine designs, develop new solutions, and implement emerging technologies.

Beyond manufacturing excellence, MacroAir is shaping the future of HVLS fan technology. The company is actively advocating for industry-wide standardization in sound testing, ensuring that customers can make informed decisions based on uniform performance metrics.

As a company, MacroAir builds fans by use case, with some applications requiring a quieter, less intrusive product. For example, a library, university lecture hall, or office will require a quieter solution as opposed to a manufacturing facility. By building products fit to specific requirements, the company is expanding the HVLS industry by meeting specific vertical market needs with its products.

General Manager Geoff Herkner affirms, "This is an area where we, MacroAir, do extensive standardized testing in-house, but, as an industry, overarching standards haven't been implemented. We advocate for more standardization around decibel testing because sound plays such a critical role in fan application. We have standardized our test process and procedures to the best of our ability for each fan and use a CESVA sound level meter and spectrum analyzer. In a perfect world, governing bodies will adopt universal standards for levels and testing."

MacroAir isn't just an American manufacturer; it is a family-owned business that values long-term relationships. Some employees have been with the company since its inception, bringing deep institutional knowledge and craftsmanship to every product.

With a lean yet highly skilled team of 50+ full-time employees, MacroAir remains agile and cost-efficient while maintaining its reputation for excellence. "Unlike larger corporations, we, at MacroAir, retain experienced workers who carry decades of expertise, ensuring consistent quality and innovation," confirms daughter of Eddie, Jaylin Krell, Senior Vice President of Sales & Marketing.

By keeping production on U.S. soil, MacroAir ensures its fans are built to last, designed to perform, and engineered with integrity. When customers choose MacroAir, they're not just investing in cutting-edge climate solutions; they're supporting American jobs, innovation, and manufacturing.

Because at the end of the day, quality isn't just a feature: it's a promise. And for MacroAir, that promise starts and ends right here in America.

© Copyright IBTimes 2024. All rights reserved.